Ceramic Capacitor: What is it?

What is a Ceramic Capacitor?

A ceramic capacitor is the most commonly used capacitor in an electronic circuit. A ceramic capacitor is used due to its small physical size and large charge storage capability. The ceramic capacitor gets its name from its use of ceramic as a dielectric medium.

We call the ceramic capacitors the “workhorses” of high-frequency capacitors. It is a polarity-less capacitor, and hence no polarity marking is available on the ceramic capacitors unlike the case of an electrolytic capacitor.

Thus it can be easily used in AC circuits. Ceramic capacitors typically are manufactured in values from 1pF to 100μF and DC working volts from 10 volts to 5000 volts.

Types of Ceramic Capacitor

Construction-wise it can be subdivided into two groups

Ceramic Disc Capacitor

Multilayer Ceramic Capacitor (MLCC)

Ceramic Disc Capacitor

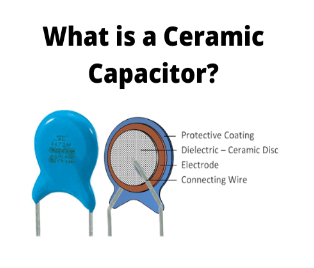

Ceramic disc capacitors usually consist of two conductive discs on each side of a piece of the ceramic insulator, one lead attached to each plate, and coated with some inert, waterproof coating of some ceramic composition.

The disc-type capacitors have a high capacitance per unit volume. They are available up to a value of 0.01 μF. It has voltage ratings up to 750 V D.C. and 350V concerning A.C.

Multilayer Ceramic Capacitor

Multilayer ceramic capacitors (MLCCs) are composed of multiple layers of ceramic material, often of barium titanate, separated by interdigitated metal electrodes. This construction places many capacitors in parallel.

Some MLCCs contain hundreds of ceramic layers; each layer behaves as a single ceramic capacitor. That means an MLCC comprises multiple layers of ceramic material, commonly of barium titanate, separated by metal electrodes as shown.

The terminal contacts are taken from both ends of the structure. Some MLCCs contain hundreds of ceramic layers, each layer only a few micrometers thick.

The total capacitance of the structure would be the product of the capacitance of each layer and the total number of layers in the capacitor.

Multilayer capacitor construction, when combined with surface mount technology, can produce almost ideal high-frequency capacitors. Some small-value (e.g., tens of pico-farads) surface mount MLCCs can have self-resonant frequencies in the multiple gigahertz ranges.

Most MLCCs have capacitance values of 1μF or less with voltage ratings of 50V or less. The small spacing between the layers limits the voltage rating.

However, the small spacing combined with a large number of layers has allowed manufacturers to produce more substantial value MLCC with capacitance values in the 10 to 100 pf range. MLCCs are excellent high-frequency capacitors and commonly used for high-frequency filtering as well as digital logic decoupling applications.

High-K (K= dielectric constant) ceramic capacitors are only medium-frequency capacitors. They are relatively unstable to time, temperature, and frequency. Their primary advantage is a higher capacitance-to-volume ratio, compared with that of standard ceramic capacitors.

They are usually used in noncritical applications for bypassing, coupling, and blocking. Another disadvantage is that voltage transients can damage them.

It is therefore not recommended to use as bypass capacitors directly across a low-impedance power supply.

Advantages of Ceramic Capacitor

The advantages of ceramic capacitors include:

Any size or shape is available in the market.

At the same time, ceramic capacitors are inexpensive.

They are light in weight, too.

They can be designed to withstand up to sufficient high voltage (up to 100V).

Their performance is reliable.

They are suitable for use in hybrid integrated circuits.

Disadvantages of Ceramic Capacitor

The disadvantages of ceramic capacitors include:

Very high-voltage ceramic capacitors are not available.

High capacitance values are not possible.

Applications of Ceramic Capacitor

The medium and high permittivity ceramic capacitors are used for bypass and decoupling applications or frequency discrimination where Q factor and stability are not major issues.

Source: Electrical4u.

Statement: Respect the original, good articles worth sharing, if there is infringement please contact delete.

Welcome to our electricity community! Established to facilitate the exchange and cooperation in the electricity industry and bridge professionals, enthusiasts, and related enterprises.