What is an Inductive Ballast?

What is an Inductive Ballast?

Inductive Ballast definition

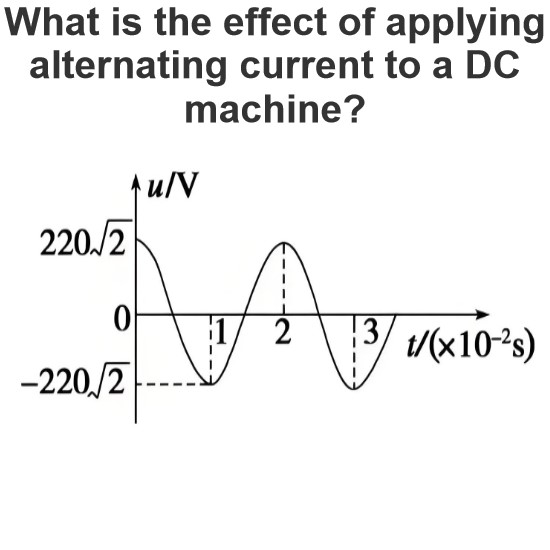

Inductive Ballast is an iron core inductance coil, the nature of inductance is that when the current in the coil changes, it will cause a change in magnetic flux in the coil, resulting in induced electromotive force, and its direction is opposite to the direction of the current change, thus hindering the current change.

Working principle of Inductive Ballast

When the 220V 50Hz AC power supply is applied in the switch closing circuit, the current flows through the Ballast, lamp filament, and spark starter to heat the filament. When the two electrodes of the starter are close together, because there is no arc discharge, the bimetal sheet is cooled, the two electrodes are disconnected, because the inductive Ballast is inductive, when the two electrodes are disconnected, the current in the circuit suddenly disappears, so the ballast produces a high pulse voltage, which is superimposed with the power supply voltage, added to both ends of the lamp, so that the inert gas in the lamp is ionized and caused by arc discharge. During the normal luminous process, the self-inductance of the ballast plays a role in stabilizing the current in the circuit.

Basic structure of Inductive Ballast

Coil: Generates induced electromotive force. In the case of power-on, because there is a certain resistance in the coil, it will produce electrical energy loss, and the generated heat energy will increase the temperature of the inductor ballast, which is easy to accelerate the aging of the ballast. In order to reduce the resistance in the coil, try to use high purity imported electrolytic copper enamelled wire.

Silicon steel sheet: The whole conductor is in the changing magnetic field, which will cause induced current inside the whole conductor, commonly known as "eddy current", which will cause the consumption of electric energy and the temperature rise. In the inductive ballast, in order to enhance the magnetic induction intensity, the iron core is used, but because of the existence of eddy currents, it is necessary to use a very thin silicon steel sheet laminated to form an iron core, rather than a whole iron core, to reduce the loss caused by eddy currents.

Bottom plate: fixed, installation function.

Skeleton: fixed coil, chip, convenient wiring function.

Terminal: plays the role of wiring, connecting the inductive ballast in series to the circuit.

Main parameters of Inductive Ballast

Rated voltage

Rated current

Rated output current

Power factor λ

Inductive Ballast installation precautions

Power supply quality problem: three-phase power supply should be balanced as far as possible, and each power supply voltage should not be too high, requiring 220V to be appropriate

Installation quality problem: Install the lamp according to the lamp diagram, ensure the installation firmly, pay attention to the installation environment.

Common fault

Due to the poor quality of the lamp, it takes a long time to start or not start.

The starting current of the ballast is too small and the starting impact time is too long.

The starting current of the ballast is too large to have a large impact on the filament, which is easy to make the lamp black and burn the lamp.

We aim to gather electrical knowledge and share it with others.