Nickel Iron Battery or Edison Battery Working and Characteristics

Which battery is becoming more popular day by day as there is a huge scope of development to turn the battery into high energy density battery for an electric vehicle? The answer would be Nickel Iron Battery or Edison Battery. In a single word, a Ni-Fe battery is a very robust battery. This battery has a very high tolerance for overcharging, over discharging, short-circuiting, etc. This battery can perform equally well even we do not charge the battery for a long period. Due to its heavy weight, this battery is used in those applications where the weight of the battery does not matter, for example, in the solar energy system, in wind energy system, etc. as a backup. Durability and lifespan of a nickel-iron cell are much higher than that of a lead acid battery, but still, the nickel-iron battery has lost its popularity because of its high manufacturing cost.

Let’s have a look at some specific features of nickel-iron (Ni-Fe) or Edison battery.

This battery can have 30 to 50 kW energy delivery capacity per kg of its weight. Charging efficiency of this battery is about 65%. That means 65% of input electrical energy gets stored in this battery as chemical energy during its charging process. Discharging efficiency is about 85%. That means the battery can deliver 85% of stored energy to the load as electrical energy and the rest gets discharged due to self-discharging of the battery. If the battery is kept unused for 30 days, it will lose only 10% to 15 % of its stored energy due to self-discharging. Nickel Iron battery has a significantly longer lifespan, and it is about 30 to 100 years. This period is much longer than the normal lifespan of a lead acid battery which is about ten years. Nominal voltage rating per nickel iron cell is 1.4 V.

Nickel Iron Battery

The basic components used in Nickel iron battery are nickel(III) hydroxide as the cathode, iron as anode and potassium hydroxide as the electrolyte. We add Nickel sulfate and Ferrous sulfide to the active material.

Construction of Edison Batteries

The capacity of Ne-Fe cell depends upon size and number of positive and negative plates. The appearance of both positive and negative plates in this type of battery cells is same. Both of the plates consist of the rectangular grid made of nickel-plated iron. Each of the grid holes is filled with shallow and finely perforated nickel-plated steel box.

Although both of the plates are appeared to be same, they contain different active materials. Perforated nickel-plated steel boxes of positive plates contain a mixture of an oxide of nickel and pulverized carbon, and some of the negative plates contain fine grains of the oxide of iron with the fine dust of carbon. In both the plates, the fine dust of carbon, mixed with active materials, helps to increase electrical conductivity. We use 20% diluted caustic potash as an electrolyte.

Nickel plated iron gets used to make the vessel containing electrolyte and electrodes. Ebonite sticks are placed between the plates of different polarities to prevent them from coming into direct contact and causing a short circuit. There is another specialty in the construction of Edison battery or nickel iron battery, which the number of negative plates is one more than that of the number of positive plates, and we electrically connect the last negative plate to the container. Plates of same polarities are welded to a common strap, and they make a cell, and combining several cells, the battery gets constructed.

Operation of Nickel Iron Batteries

We already know that the main operation of the nickel-iron battery is the chemical reaction within the battery which is known as electrolysis. Electrolysis is nothing but the chemical reaction taking place when there is current flow, it can be both cause and result of the chemical reaction. The chemistry of nickel-iron cell is very much complicated because the exact formula for the positive active material is not well established yet. But if we can assume that the material to be Ni(OH)3, then we can explain it to some extent. During charging, nickel compound at the positive plates gets oxidized to nickel peroxide. Charging process changes iron compound to spongy iron in negative plates.

In the fully charged condition, the active material of the positive plates is nickel hydroxide [Ni(OH)3], while that in pockets of the negative plate is iron, Fe. When the cell delivers current to load, the active material of the positive plate changes from Ni(OH)3 to Ni(OH)2 and that of the negative plate changes from iron to Ferrous hydroxide (Fe(OH)2). The electrochemical process in the Edison battery can be expressed by the equation

The equation expresses both the phenomenon of charging and discharging. The right side flow of the equation is the reaction of the discharging phenomenon, and the left side flow of the equation expresses the charging phenomenon. The reaction occurs by transfer of electrons through the external circuit to the positive plate during discharge. There is a provision for giving off the corrosive fume which is generated during the electrolysis inside the battery so that no special care is needed in mounting the cell.

Characteristics of Nickel Iron Batteries

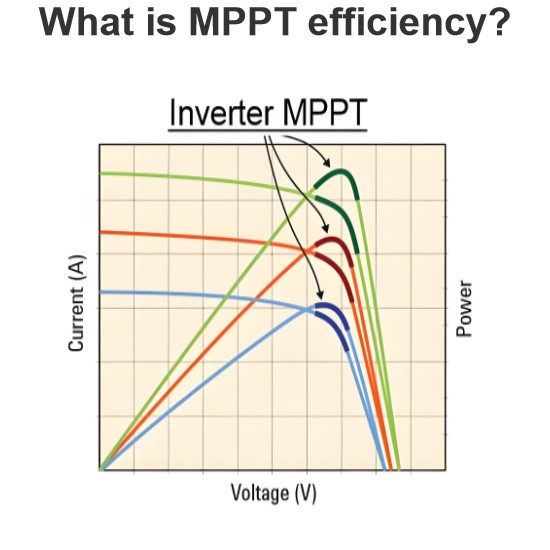

The emf of a fully charged Edison battery is 1.4 V. The average discharge voltage is about 1.2 V and the average charging voltage is about 1.7 V per cell. The characteristics of this type of battery are shown below in the figure.

The voltage characteristics of the Nickel Iron battery are similar to that of the lead-acid cell. As the fully charged emf 1.4 V and it slowly decreases to 1.3 V and then very slowly to 1.1 or 1.0 V during discharge. From the graph, we can see that there is no lower limit for discharging emf beyond which the output of the battery will be zero. That’s why after a certain period the battery stop to any output. The emf of a battery is directly proportional to the temperature, which means the emf of the battery increases with increase in temperature.

The average time of charging of a battery is 7 hours and discharging time is 5 hours. Another characteristic of Edison battery is that continuous operation at higher temperature decreases the life of the battery, the same thing happens if the battery is charged for more than the average time of charging.

The ampere-hour and watt-hour efficiency of this nickel-iron battery is 85 % and 60 % respectively. At 4oC temperature, the capacity of Edison battery falls to zero, that’s why the battery should be heated up before operation though during operation the I2R loss keeps the battery hot and running.

Advantages of Nickel Iron Batteries

There are various Advantages of Edison battery , these are listed below.

The weight of this battery is lower than other types of battery because they need less amount of electrolytes and plates are also lighter.

The service life of the battery is much higher because of various provisions made.

These types of battery are stronger, have rugged construction because of the steel body. For this reason, they are not affected by vibrations, jolts or shocks, heavy currents and do not suffer during short circuits.

Disadvantages of Nickel Iron Batteries

There are certain disadvantages of Edison battery, like the initial cost needed for making these batteries are pretty high as the materials used are highly priced. Another drawback of these type of battery is the low efficiency. For this few reasons the use of these batteries is restricted, they are mainly used in the areas where high mechanical strength, lightness, freedom from acid fumes are needed.

Statement: Respect the original, good articles worth sharing, if there is infringement please contact delete.

Electrical4U is dedicated to the teaching and sharing of all things related to electrical and electronics engineering.