Metal Halide Lamps: A Comprehensive Guide

A metal halide lamp is a type of high-intensity discharge (HID) lamp that produces light by an electric arc through a gaseous mixture of vaporized mercury and metal halides. Metal halides are compounds of metals with bromine or iodine. Metal halide lamps have high luminous efficacy, color rendition, and long lifespan. They are widely used for general lighting purposes both indoors and outdoors, such as commercial, industrial, and public spaces, parking lots, sports arenas, factories, and retail stores, as well as residential security lighting and automotive headlights.

What is a Metal Halide Lamp?

A metal halide lamp is defined as an electrical lamp that produces light by an electric arc through a gaseous mixture of vaporized mercury and metal halides. The electric arc is created between two electrodes inside a small fused quartz or ceramic arc tube, which is enclosed inside a larger glass bulb that has a coating to filter out the ultraviolet light produced. The arc tube operates at a high pressure of 4 to 20 atmospheres and a high temperature of about 1000 K.

The metal halides used in the lamp are usually sodium iodide, indium iodide, and thallium iodide. These compounds improve the efficiency and color rendition of the light by adding orange and reds to the spectrum from the sodium D line and green to the spectrum from the thallium line as the metal ions ionize. The most common metal halide compound used is sodium iodide. The metal halides also help to stabilize the arc and reduce the flickering of the light.

Metal halide lamps have a high luminous efficacy of around 75 to 100 lumens per watt, which is about twice that of mercury vapor lamps and 3 to 5 times that of incandescent lamps. They also have high color rendering index (CRI) of 65 to 95, which means they can reproduce colors accurately. Metal halide lamps have a lifespan of 6,000 to 15,000 hours, depending on the type and wattage of the lamp.

Who Invented Metal Halide Lamps?

Metal halide lamps were invented by Charles Proteus Steinmetz in 1912, but they were not commercially available until the 1960s. Dr. Reiling from General Electric was one of the pioneers who developed metal halide lamps in 1960. He used sodium iodide as the metal additive in his lamp. Later, other researchers experimented with different metal halides, such as indium iodide, thallium iodide, scandium iodide, and dysprosium iodide.

How Does a Metal Halide Lamp Work?

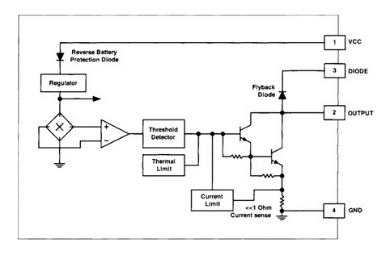

A metal halide lamp works by creating an electric arc between two electrodes inside an arc tube that contains a gaseous mixture of vaporized mercury and metal halides. The arc tube is connected to an electrical ballast that regulates the voltage and current supplied to the lamp.

When the lamp is switched on, no arc is produced at first because the gas pressure and temperature inside the arc tube are too low. To start the lamp, an auxiliary electrode or a starter electrode near one of the main electrodes creates an initial discharge between them. A bimetal switch shorts the starter electrode to the main electrode just at the time of starting.

The initial discharge heats up the gas mixture inside the arc tube and ionizes some of the argon gas and mercury vapor. This creates a low-intensity arc between the main electrodes that gradually increases in brightness and temperature as more gas molecules are ionized.

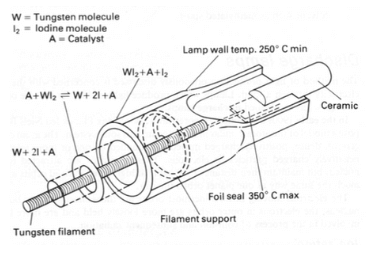

As the arc temperature rises, the metal halides vaporize and diffuse from the wall into the arc stream. Then they dissociate and yield free metal and iodine atoms. The metal atoms produce most of the light output by emitting visible radiation when they return to their ground state after being excited by the electric arc.

The different metal halides vaporize at different rates depending on their vapor pressure and energy level configuration. Generally, indium iodide vaporizes first and forms a blue sheath around the mercury arc. Then thallium iodide vaporizes and forms a yellow sheath around the indium sheath. Finally, sodium iodide vaporizes and adds orange and red to the spectrum.

The lamp reaches its full light output after about 5 minutes of warming up. During this time, the color temperature and CRI of the lamp change as more metal halides are vaporized.

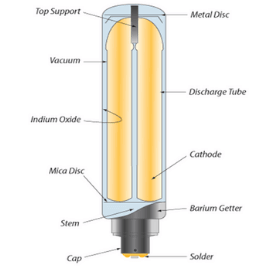

What are the Components of a Metal Halide Lamp?

A metal halide lamp consists of several components that work together to produce light. These components are:

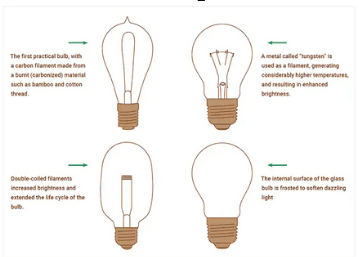

Glass bulb: This is the outer envelope that encloses the arc tube and protects it from air and moisture. It also has a coating to filter out the ultraviolet light produced by the arc.

Arc tube: This is a small fused quartz or ceramic tube that contains the electrodes and the gas mixture of vaporized mercury and metal halides. It operates at a high pressure and temperature.

Electrodes: These are two tungsten rods that are sealed into opposite ends of the arc tube. They create an electric arc between them when current flows through them.

Starter electrode: This is an auxiliary electrode that is attached to one of the main electrodes or to a glass stem near them. It creates an initial discharge between itself and another electrode to start the lamp. The starter electrode has a high resistance to limit the current at the initial arc.

Glass stem: This is a glass tube that connects the arc tube to the base of the lamp. It also holds the molybdenum wires that carry the current to the electrodes.

Molybdenum wires: These are thin metal wires that are fused into the arc tube and the glass stem. They are non-magnetic and have a high melting point. They transmit the current to the electrodes and seal the arc tube from air and moisture.

Base: This is the part of the lamp that connects to the socket or lamp holder. It can have different shapes and sizes depending on the type and wattage of the lamp. Some common base types are E26, E39, G12, G8.5, GX10, RX7s, and RX7s-24.

Gas mixture: This is a combination of argon gas, mercury vapor, and metal halides that fills the arc tube. The argon gas helps to start the lamp and maintain a low arc voltage. The mercury vapor provides most of the ultraviolet radiation that excites the metal atoms. The metal halides add visible radiation and improve the color rendition of the light.

What are the Advantages and Disadvantages of Metal Halide Lamps?

Metal halide lamps have many advantages and disadvantages compared to other types of lamps. Some of them are:

Advantages

High luminous efficacy: Metal halide lamps can produce more light per watt than incandescent lamps and most fluorescent lamps. They can reach up to 100 lumens per watt for some types of lamps.

High color rendering index: Metal halide lamps can reproduce colors accurately with a CRI of 65 to 95. They can also produce a range of color temperatures from warm white to daylight white, depending on the type and wattage of the lamp.

Long lifespan: Metal halide lamps can last up to 15,000 hours for some types of lamps, which is longer than incandescent lamps and comparable to fluorescent lamps.

Small size: Metal halide lamps are small compared to incandescent and fluorescent lamps with the same light output. This makes them suitable for compact and efficient fixtures and applications.

Versatile: Metal halide lamps can be used for various applications both indoors and outdoors, such as general lighting, security lighting, automotive lighting, stage lighting, photographic lighting, and grow lighting.

Disadvantages

Warm-up period: Metal halide lamps require several minutes to reach full light output after being switched on. They also need a cool-down period before they can be restarted. This makes them unsuitable for applications that require frequent switching or instant brightness.

High initial cost: Metal halide lamps are more expensive than incandescent and fluorescent lamps in terms of initial purchase price. They also require special fixtures and ballasts to operate safely and efficiently, which adds to the cost.

High operating temperature: Metal halide lamps operate at a high temperature of about 1000 K inside the arc tube. This can cause heat damage to the lamp components and surrounding materials if not properly ventilated or cooled.

Ultraviolet radiation: Metal halide lamps produce ultraviolet radiation that can be harmful to humans, animals, plants, and materials if not filtered out by the glass bulb or a separate shield. Ultraviolet radiation can also cause color fading and degradation of some materials over time.

Flickering: Metal halide lamps can flicker due to fluctuations in voltage, current, or frequency. Flickering can affect the quality and stability of the light output and cause eye strain or headaches for some people.

How to Choose a Metal Halide Lamp?

There are many factors to consider when choosing a metal halide lamp for a specific application. Some of them are:

Wattage: This is the amount of power consumed by the lamp. It determines the light output, energy efficiency, and operating cost of the lamp. Higher-wattage lamps produce more light but also consume more energy and generate more heat. Lower-wattage lamps produce less light but also consume less energy and generate less heat.

Color temperature: This is a measure of how warm or cool the light appears. It is expressed in kelvins (K). Higher color temperatures produce cooler light with more blue tones, while lower color temperatures produce warmer light with more red tones. The color temperature of metal halide lamps ranges from 3000 K (warm white) to 6500 K (daylight white), depending on the type and wattage of the lamp. The color temperature of metal halide lamps affects the mood and ambiance of the space as well as the visibility and contrast of objects.

Color rendering index: This is a measure of how well the lamp reproduces the colors of objects compared to a natural light source. It is expressed as a number from 0 to 100, with 100 being the best. Higher CRI lamps show colors more accurately and vividly, while lower CRI lamps distort or dull colors. The CRI of metal halide lamps ranges from 65 to 95 depending on the type and wattage of the lamp. Higher CRI lamps are preferred for applications that require color accuracy, such as retail stores, museums, and art galleries.

Base type: This is the shape and size of the part of the lamp that connects to the socket or lamp holder. It determines the compatibility and interchangeability of the lamp with different fixtures and ballasts. There are several different base types for metal halide lamps, such as E26, E39, G12, G8.5, GX10, RX7s, and RX7s-24. The base type should match the socket or lamp holder of the fixture or ballast.

Lamp shape: This is the shape and size of the outer glass bulb that encloses the arc tube. It affects the light distribution and beam angle of the lamp. There are various lamp shapes for metal halide lamps, such as ED (elliptical), BT (bulged tubular), PAR (parabolic aluminized reflector), MR (multifaceted reflector), T (tubular), and R (reflector). The lamp shape should suit the application and fixture design.

Lamp size: This is the length and diameter of the lamp measured in millimeters or inches. It affects the fit and clearance of the lamp in different fixtures and ballasts. The lamp size should be compatible with the fixture or ballast specifications.

How to Maintain a Metal Halide Lamp?

Metal halide lamps require proper maintenance to ensure their optimal performance and longevity. Some of the maintenance tips are:

Use appropriate fixtures and ballasts: Metal halide lamps require special fixtures and ballasts to operate safely and efficiently. The fixtures should have adequate ventilation and cooling to prevent overheating and thermal stress on the lamp components. The ballasts should match the voltage, wattage, base type, and operating position of the lamp. The ballasts should also have proper grounding and protection against power surges and short circuits.

Follow manufacturer’s instructions: Metal halide lamps should be installed, operated, and replaced according to the manufacturer’s instructions. The instructions should include information on lamp orientation, burning cycle, warm-up time, cool-down time, restrike time, dimming capability, end-of-life indication, disposal method, and warranty terms.

Avoid frequent switching: Metal halide lamps should not be switched on and off frequently or abruptly. Frequent switching can reduce the lamp life and cause flickering or cycling. Metal halide lamps should be operated for at least 10 hours per start (except for M1500 and BRITELINE lamps, which are based on 5 hours per start) to achieve their rated life.

Replace lamps timely: Metal halide lamps should be replaced when they reach their end-of-life or show signs of deterioration, such as reduced light output, color shift, flickering, cycling, or blackening. Replacing lamps timely can prevent premature failure or explosion of the arc tube that can damage the fixture or ballast or cause injury to people.

Dispose of lamps properly: Metal halide lamps contain mercury and other hazardous substances that can harm human health and the environment if not disposed of properly. Metal halide lamps should be recycled or disposed of according to local regulations or guidelines. They should not be thrown in regular trash bins or incinerators.

Conclusion

Metal halide lamps are a type of high-intensity discharge (HID) lamp that produces light by an electric arc through a gaseous mixture of vaporized mercury and metal halides. They have high luminous efficacy, color rendition, and lifespan. They are widely used for general lighting purposes both indoors and outdoors. They require special fixtures and ballasts to operate safely and efficiently. They also require proper maintenance to ensure their optimal performance and longevity.

Statement: Respect the original, good articles worth sharing, if there is infringement please contact delete.

Welcome to our electricity community! Established to facilitate the exchange and cooperation in the electricity industry and bridge professionals, enthusiasts, and related enterprises.