High Pressure Sodium Vapor Lamp: Definition, Working, and Applications

A high pressure sodium vapor lamp is a type of gas-discharge lamp that uses sodium in an excited state to produce light. It is one of the most efficient types of lighting sources and has a long lifespan. It is widely used for industrial lighting and outdoor security areas, such as parking lots and roadways.

What is a High Pressure Sodium Vapor Lamp?

A high pressure sodium vapor lamp is defined as a lamp that operates at a high pressure (above 1 atm) and temperature (above 1000 °C) inside a translucent ceramic arc tube made of polycrystalline alumina (PCA). The arc tube contains a mixture of xenon gas, sodium-mercury amalgam, and electrodes at both ends. The arc tube is enclosed in a heat-resistant outer glass bulb that is evacuated or filled with inert gas.

The lamp works by applying a high voltage pulse from a ballast and an igniter to the electrodes, which ionizes the xenon gas and creates an initial arc. The arc heats up the arc tube and vaporizes the mercury and sodium. The mercury vapor emits a bluish-white light, while the sodium vapor emits a yellow light. The combination of these two spectra results in a golden-white light with a color temperature of about 2000 K and a color rendering index of about 25.

The high pressure sodium vapor lamp has several advantages over other types of lamps, such as:

High luminous efficacy: It can produce up to 150 lumens per watt, which is about twice as much as mercury vapor lamps and five times as much as incandescent lamps.

Long lifespan: It can last up to 24,000 hours, which is about four times as long as mercury vapor lamps and 24 times as long as incandescent lamps.

Low maintenance: It does not require frequent replacement or cleaning, which reduces labor and disposal costs.

High reliability: It can withstand voltage fluctuations, vibrations, and extreme temperatures, which makes it suitable for harsh environments.

However, the high pressure sodium vapor lamp also has some drawbacks, such as:

Poor color rendering: It has a low color rendering index, which means it distorts the colors of the objects it illuminates. This makes it unsuitable for applications where color accuracy is important, such as retail stores or museums.

Glare: It produces a bright and intense light that can cause discomfort or impairment to the vision of drivers or pedestrians. This can be reduced by using proper shielding or diffusing devices.

Cycling: It can experience cycling or flickering when it reaches the end of its life or when it operates at low temperatures. This can be prevented by using proper ballast or thermal insulation.

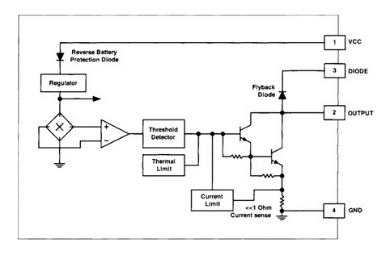

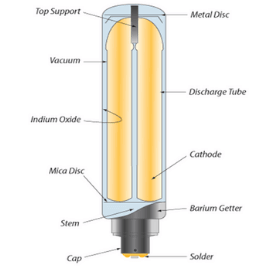

Diagram of High Pressure Sodium Vapor Lamp

The following diagram shows the main components of a high pressure sodium vapor lamp:

Outer glass bulb: It protects the arc tube from physical damage and thermal shock. It also filters out harmful ultraviolet radiation from the arc.

Arc tube: It is made of polycrystalline alumina (PCA), which is resistant to corrosion by sodium vapor. It contains the electrodes, xenon gas, and sodium-mercury amalgam.

Electrodes: They are made of tungsten wire with an emissive coating. They are connected to the ballast and the igniter through metal caps.

Xenon gas: It is used as a starting gas because it has a low ionization potential. It also contributes to the light output by emitting blue light.

Sodium-mercury amalgam: It is used as the main light source because it emits yellow light with high luminous efficacy. It is stored in a reservoir behind one of the electrodes.

Ballast: It is an electrical device that regulates the current and voltage to the lamp. It also provides the high voltage pulse for starting the lamp.

Igniter: It is an electronic device that generates the high voltage pulse for starting the lamp by superimposing it on the supply voltage.

Applications of High Pressure Sodium Vapor Lamp

The high pressure sodium vapor lamp is mainly used for applications where high brightness, long lifespan, and low maintenance are required, such as:

Street lighting: High-pressure sodium vapor lamps are widely used for lighting public streets, highways, bridges, tunnels, and other outdoor areas. They provide high brightness, long lifespan, and low maintenance. They also have a low glare factor and high color stability over time. However, they have poor color rendering and low visual acuity, which can affect the safety and comfort of drivers and pedestrians.

Industrial lighting: High-pressure sodium vapor lamps are also used for lighting various industrial applications, such as warehouses, factories, workshops, mines, power plants, and stadiums. They provide high luminous efficacy, high reliability, and high resistance to harsh environments. They also have high lumen maintenance and a low depreciation rate. However, they have poor color rendering and a high warm-up time, which can affect the productivity and quality of work.

Horticultural lighting: High-pressure sodium vapor lamps are also used for lighting indoor plants and greenhouses. They provide high photosynthetic active radiation (PAR), which stimulates the growth and flowering of plants. They also have a long lifespan and low energy consumption. However, they have a high heat output and a low spectral quality, which can affect the health and diversity of plants.

Advertising lighting: High-pressure sodium vapor lamps are also used for lighting billboards, signs, monuments, and other outdoor displays. They provide high brightness, long lifespan, and low maintenance. They also have a high contrast ratio and high visibility at night. However, they have poor color rendering and a low color temperature, which can affect the attractiveness and readability of the displays.

Comparison of High-Pressure Sodium Vapor Lamp with Low-Pressure Sodium Vapor Lamp

A low-pressure sodium vapor lamp is another type of gas-discharge lamp that uses sodium in an excited state to produce light. It operates at low pressure (below 0.1 atm) and temperature (below 300 °C) inside a glass arc tube that contains sodium vapor and neon gas. The arc tube is enclosed in an outer glass bulb that is filled with inert gas or vacuum.

The lamp works by applying a voltage to the electrodes at both ends of the arc tube, which ionizes the neon gas and creates an initial arc. The arc heats up the arc tube and vaporizes the sodium. The sodium vapor emits a monochromatic yellow light with a wavelength of 589 nm.

The low-pressure sodium vapor lamp has some advantages over the high-pressure sodium vapor lamp, such as:

Higher luminous efficacy: It can produce up to 200 lumens per watt, which is about 30% more than the high-pressure sodium vapor lamp.

Longer lifespan: It can last up to 30,000 hours, which is about 25% more than the high-pressure sodium vapor lamp.

Lower cost: It has a lower initial cost and a lower operating cost than the high-pressure sodium vapor lamp.

However, the low-pressure sodium vapor lamp also has some drawbacks compared to the high-pressure sodium vapor lamp, such as:

Poorer color rendering: It has a very low color rendering index of about 0, which means it completely distorts the colors of the objects it illuminates.

Lower color temperature: It has a very low color temperature of about 1700 K, which means it produces a very warm and dull light.

Larger size: It has a larger size and weight than the high-pressure sodium vapor lamp.

Cycling: It can experience cycling or flickering when it reaches the end of its life or when it operates at low temperatures.

Environmental and Health Impacts of High-Pressure Sodium Vapor Lamp

The high-pressure sodium vapor lamp has some environmental and health impacts that need to be considered before using it.

Mercury pollution: The high-pressure sodium vapor lamp contains mercury as one of its components. Mercury is a toxic metal that can cause serious health problems if ingested or inhaled. Mercury can also leak from broken or disposed lamps into the soil or water sources, where it can accumulate in the food chain and affect wildlife and humans. Therefore, proper handling and recycling of mercury-containing lamps are essential to prevent mercury pollution.

Light pollution: The high-pressure sodium vapor lamp produces bright and intense light that can cause light pollution in urban areas. Light pollution is the excessive or inappropriate use of artificial light that can interfere with natural cycles of light and dark. Light pollution can have negative effects on astronomy, ecology, human health, energy consumption, and aesthetics.

Ultraviolet radiation: The high-pressure sodium vapor lamp emits a small amount of ultraviolet (UV) radiation from the arc. UV radiation can cause skin damage, eye irritation, and immune system suppression in humans and animals. UV radiation can also degrade some materials, such as plastics and fabrics. Therefore, proper shielding or filtering of UV radiation is necessary to protect the health and safety of the users and the environment.

Electromagnetic interference: The high-pressure sodium vapor lamp generates electromagnetic interference (EMI) from the ballast and the igniter. EMI can affect the performance and operation of other electronic devices, such as radios, televisions, computers, and phones. EMI can also interfere with the communication and navigation systems of aircraft and vehicles. Therefore, proper shielding or filtering of EMI is required to comply with the standards and regulations of electromagnetic compatibility (EMC).

Future Trends and Developments of High-Pressure Sodium Vapor Lamp

The high-pressure sodium vapor lamp is facing increasing competition from other types of lighting sources, especially light-emitting diodes (LEDs). LEDs have several advantages over high-pressure sodium vapor lamps, such as:

Higher luminous efficacy: LEDs can produce up to 200 lumens per watt, which is comparable or higher than high-pressure sodium vapor lamps.

Longer lifespan: LEDs can last up to 50,000 hours, which is more than twice as long as high-pressure sodium vapor lamps.

Better color rendering: LEDs have a high color rendering index of above 80, which means they can reproduce the colors of the objects they illuminate more accurately than high-pressure sodium vapor lamps.

Lower color temperature: LEDs have a lower color temperature of about 3000 K to 5000 K, which means they produce a cooler and more natural light than high-pressure sodium vapor lamps.

Smaller size: LEDs have a smaller size and weight than high-pressure sodium vapor lamps.

Dimmable: LEDs can be dimmed easily and smoothly without affecting their lifespan or efficiency.

Controllable: LEDs can be controlled individually or in groups by using sensors, timers, switches, or remote devices.

Environmentally friendly: LEDs do not contain mercury or other hazardous substances that can pollute the environment.

Statement: Respect the original, good articles worth sharing, if there is infringement please contact delete.

Welcome to our electricity community! Established to facilitate the exchange and cooperation in the electricity industry and bridge professionals, enthusiasts, and related enterprises.