What is the Operating Principle of DC Motor?

What is the Operating Principle of DC Motor?

DC Motor Definition

A DC motor is defined as a device that converts direct electrical energy into mechanical energy using magnetic fields and electrical currents.

The following are the basic steps of the working principle of DC motors:

Excitation field: When a DC power supply supplies power to the windings in the stator (fixed part), a constant magnetic field is generated in the windings.

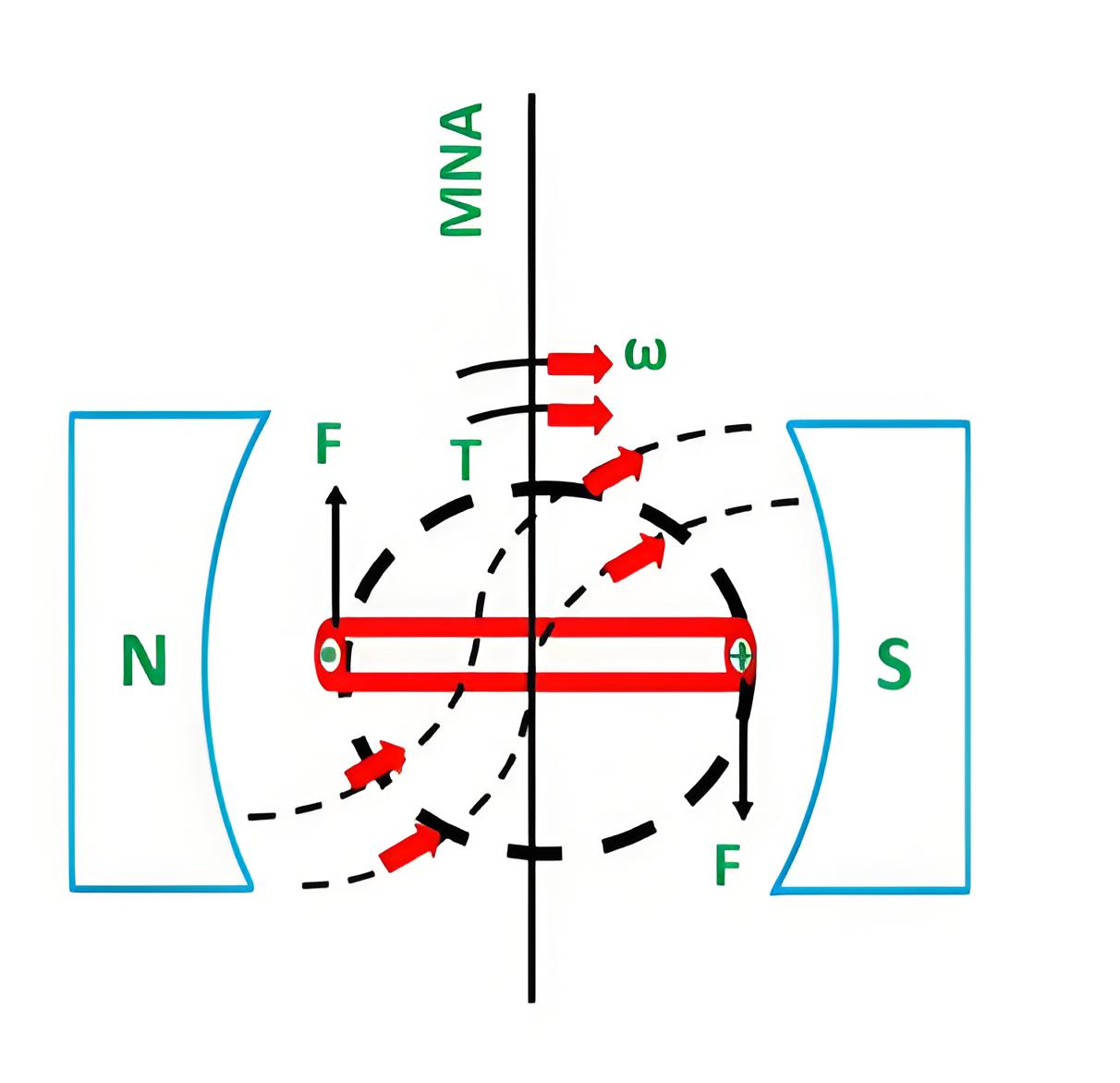

Electromagnetic force: When a current passes through the winding of the rotor (the rotating part), a magnetic field is also generated in the rotor winding. The magnetic field in the rotor winding interacts with the magnetic field generated by the stator winding to generate the electromagnetic force.

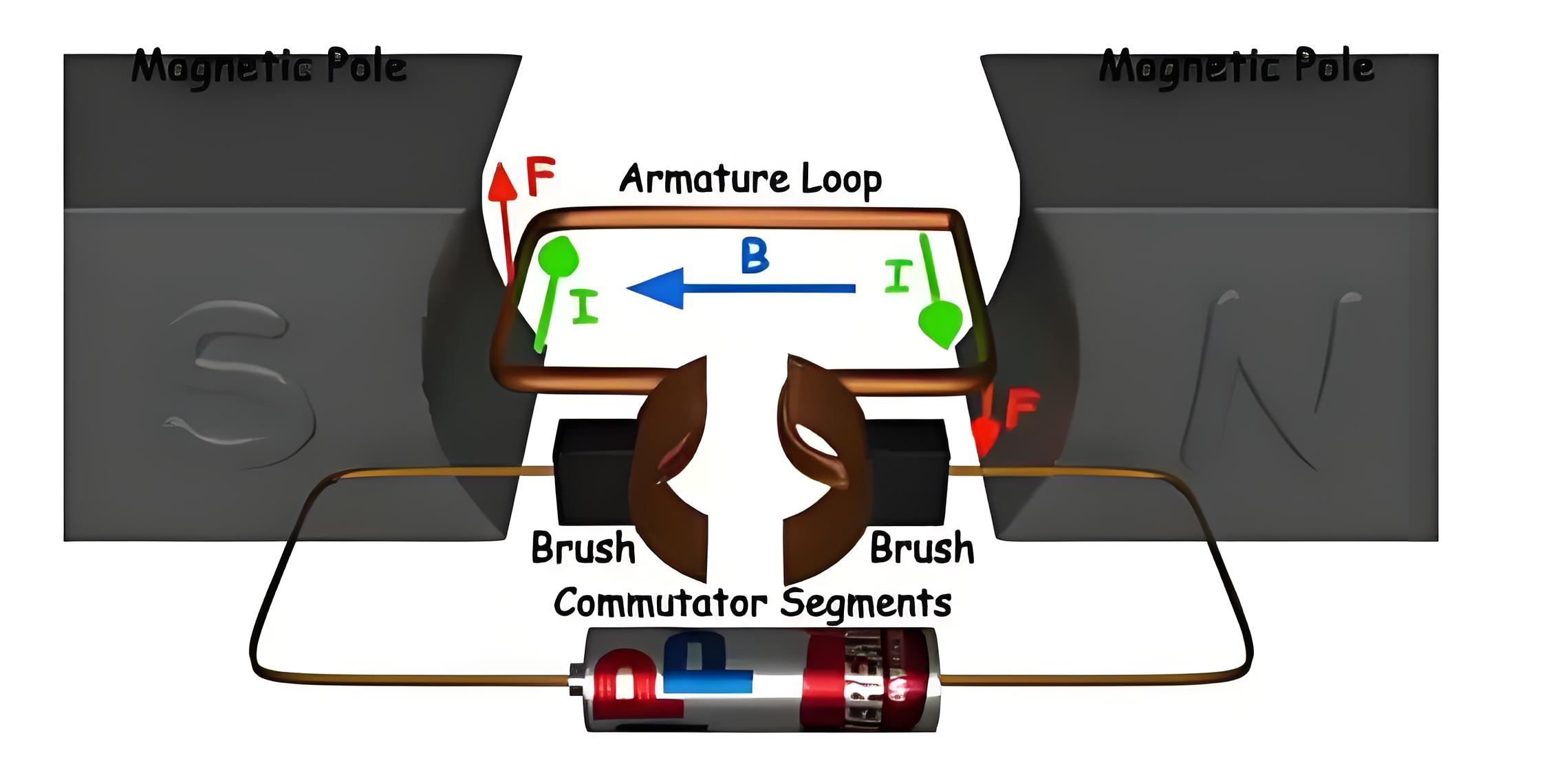

Rotational motion: Electromagnetic force is applied to the rotor, causing the rotor to start rotating. With the action of the commutator and brushes, the direction of the current changes with the rotation of the rotor, ensuring that the rotor continues to rotate in the same direction.

Commutator and brush: The commutator is a set of copper sheets, connected to the winding on the rotor, when the rotor rotates, the brush contacts with different copper sheets, thereby changing the direction of the current to ensure that the rotor continues to rotate.

Structural characteristics

Stator: Fixed in a housing, usually containing a permanent magnet or electromagnet.

Rotor: contains winding and commutator, mounted on bearing, can be freely rotated inside the stator.

Commutator: Composed of multiple copper sheets connected to the rotor winding, used to change the direction of the current.

Brush: In contact with the commutator, used to introduce current into the rotor winding.

Application scenario

Household appliances: such as vacuum cleaners, fans, blenders, etc.

Industrial equipment: Used in conveying systems, pumps, compressors, etc.

Toys: Motors used in toys such as remote control cars and robots.

Electric vehicles: Although modern electric vehicles tend to use AC motors, some small electric vehicles may still use DC motors.

Precision instruments: such as small motors in laboratory equipment.

Matters needing attention

Maintenance: Check brush and commutator wear regularly and replace if necessary.

Heat dissipation: Ensure that the motor has enough heat dissipation to avoid overheating.

Load matching: Select a motor that matches the application to ensure optimal performance.

Advantage

Simple: The structure is relatively simple, easy to understand and maintain.

Good controllability: Speed and torque can be easily controlled by adjusting voltage or current.

Cost-effectiveness: For many applications, DC motors are more cost-effective.

Shortcoming

Commutator wear: Friction between the commutator and the brush can cause wear and require regular maintenance.

Limitations: DC motors are not suitable for applications that require high speed or high power.

Welcome to our electricity community! Established to facilitate the exchange and cooperation in the electricity industry and bridge professionals, enthusiasts, and related enterprises.