What is a Squirrel Cage Induction Motor ?

What is a Squirrel Cage Induction Motor ?

Squirrel-cage induction motor definition

A squirrel cage induction motor is a motor with a rotor that looks like a squirrel cage and operates based on electromagnetism. The rotor is a steel-laminated cylindrical assembly containing a highly conductive metal such as aluminum or copper. When alternating current flows through the stator windings, it creates a rotating magnetic field. The process induces an electric current in the rotor, which creates its own magnetic field, which interacts with the stator's field to create torque.

Working principle

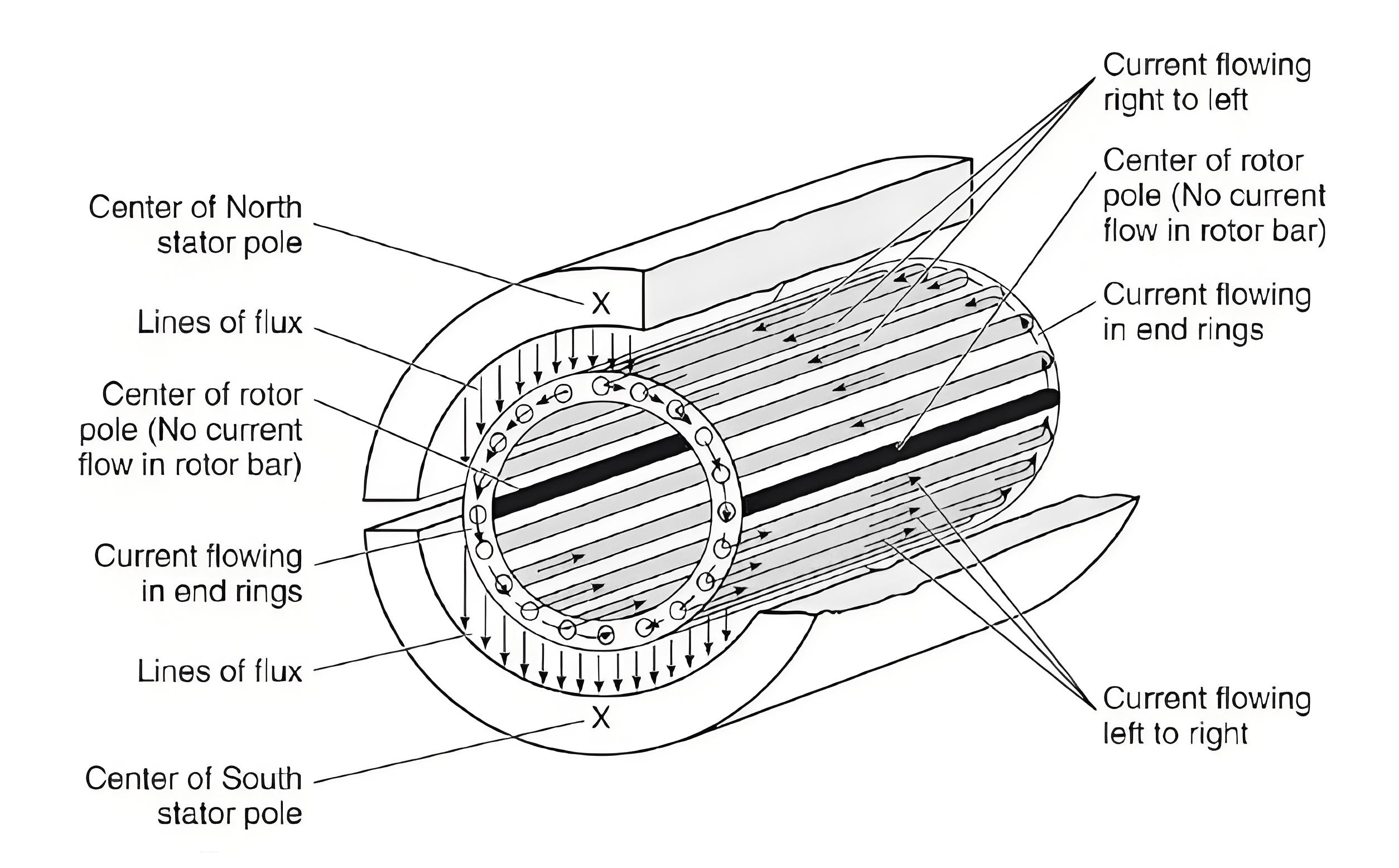

When a three-phase power supply is provided to the stator winding, it establishes a rotating magnetic field in the space. The speed at which the magnetic field rotates is called the synchronous speed.

This rotating magnetic field induces a voltage in the rotor rod, so the short-circuit current begins to flow in the rotor rod. These rotor currents generate a self-magnetic field that will interact with the stator's magnetic field. Now the rotor field will try to do the opposite of its cause, so the rotor begins to follow the rotating magnetic field.

When the rotor captures the rotating magnetic field, the rotor current drops to zero because there is no longer relative motion between the rotating magnetic field and the rotor. Therefore, at that moment, the tangential force on the rotor is zero, so the rotor is temporarily slowed down. After the rotor is slowed down, the relative motion between the rotor and the rotating magnetic field is re-established, so the rotor current is induced again. As a result, the tangential force of the rotation of the rotor recovers again, so that the rotor begins to follow the rotating magnetic field again, such that the rotor maintains a constant speed that is only less than the speed of the rotating magnetic field or the synchronization speed.

Slip measures the difference in speed between the rotating magnetic field and the rotor. The rotor current frequency is equal to the slip multiplied by the power supply frequency.

Squirrel cage induction motor structure

The squirrel cage induction motor consists of the following parts:

Stator

Rotor

Fan

Bearing

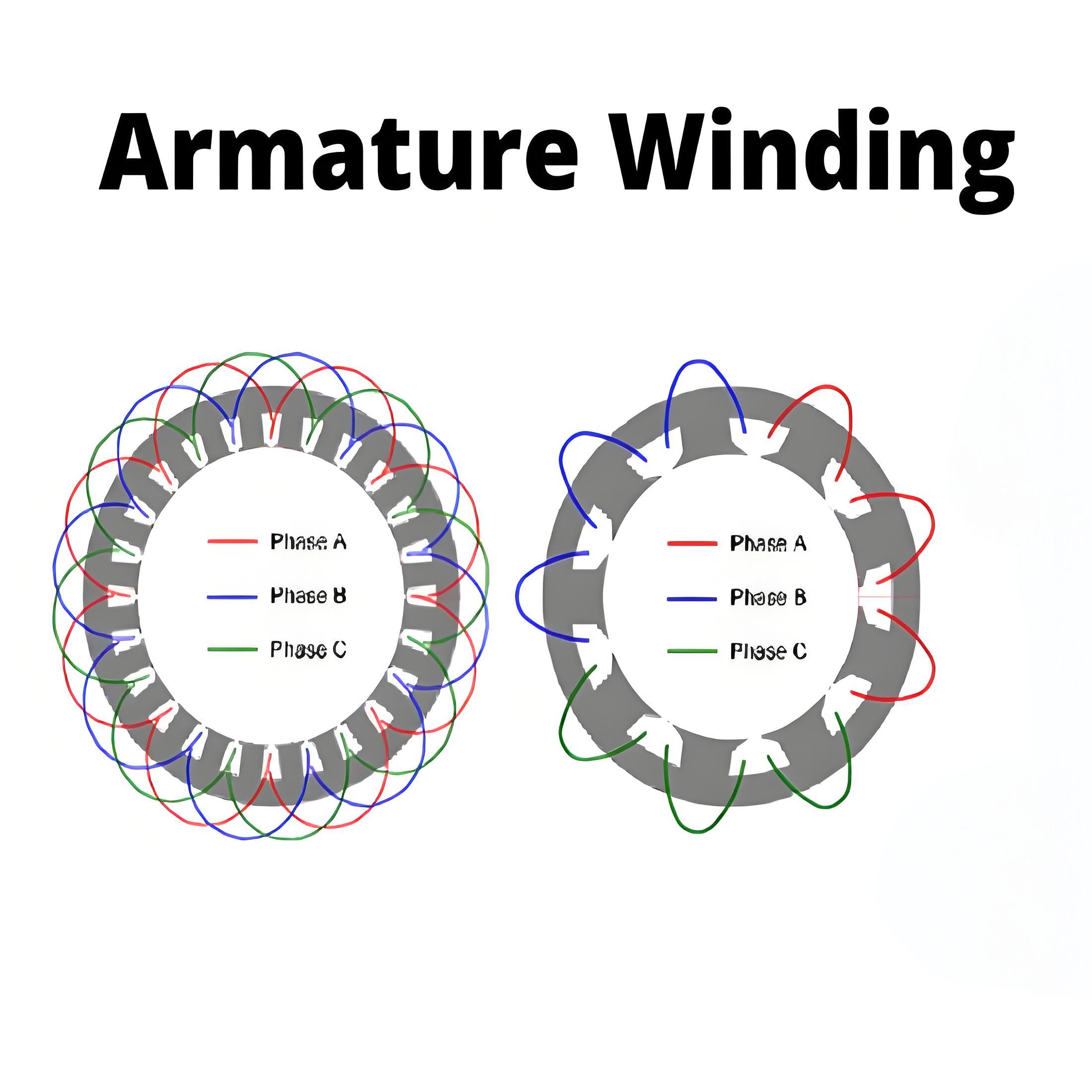

Stator

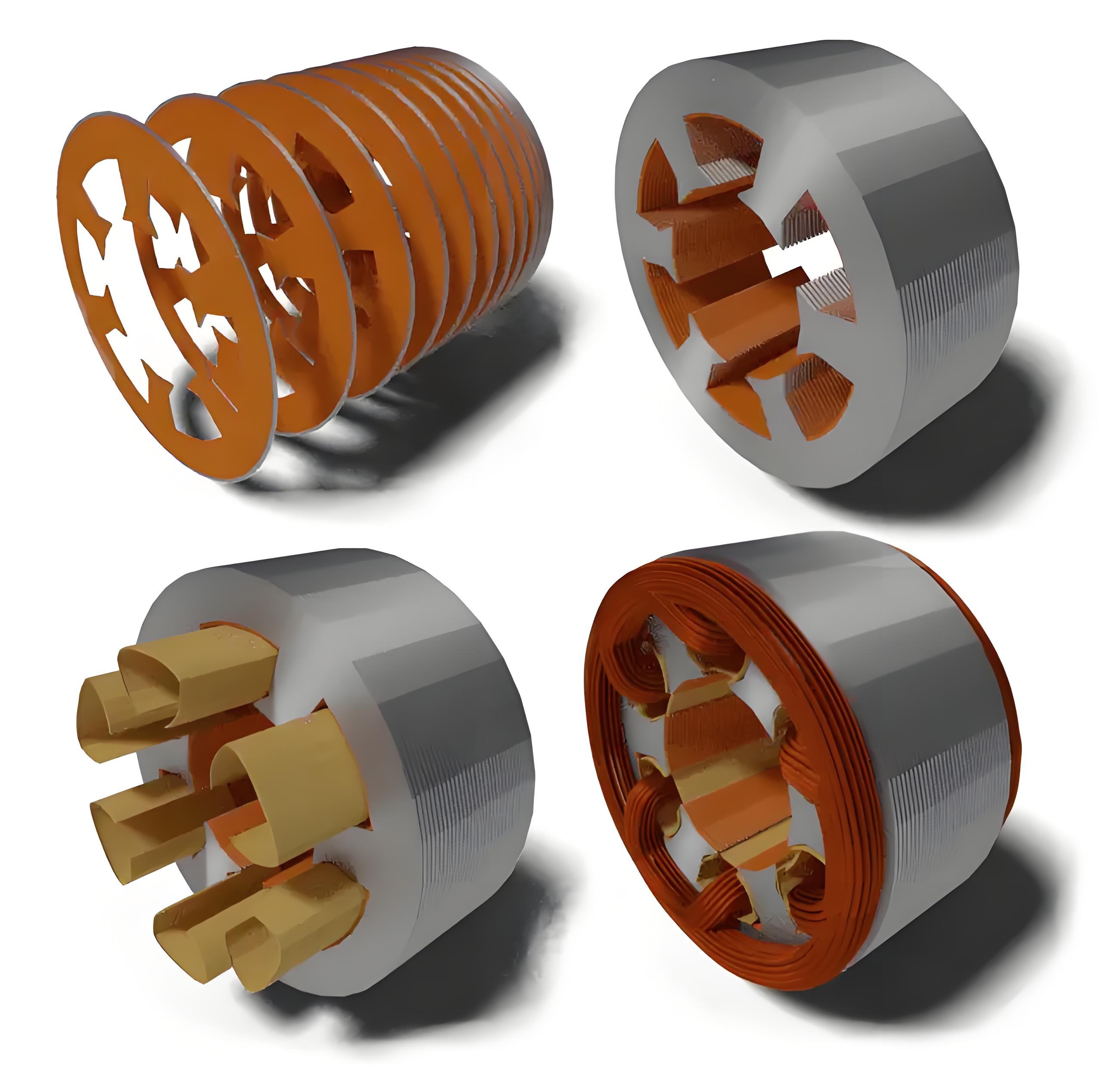

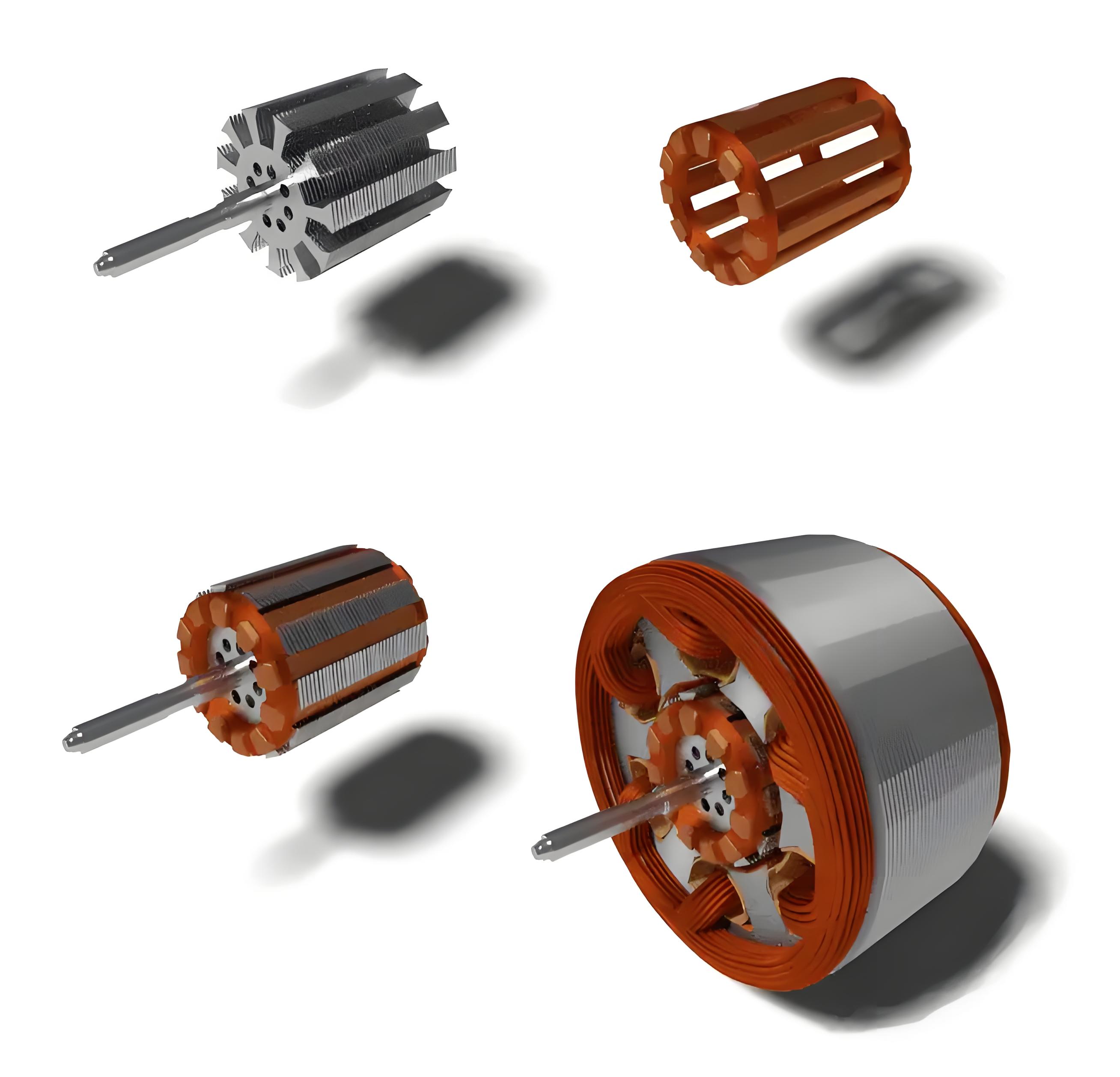

It consists of a three-phase winding with an iron core and a metal housing. The position of the winding makes it electrically and mechanically 120o except in space. The windings are mounted on a laminated iron core and provide a low-resistance path for the magnetic flux generated by the AC current.

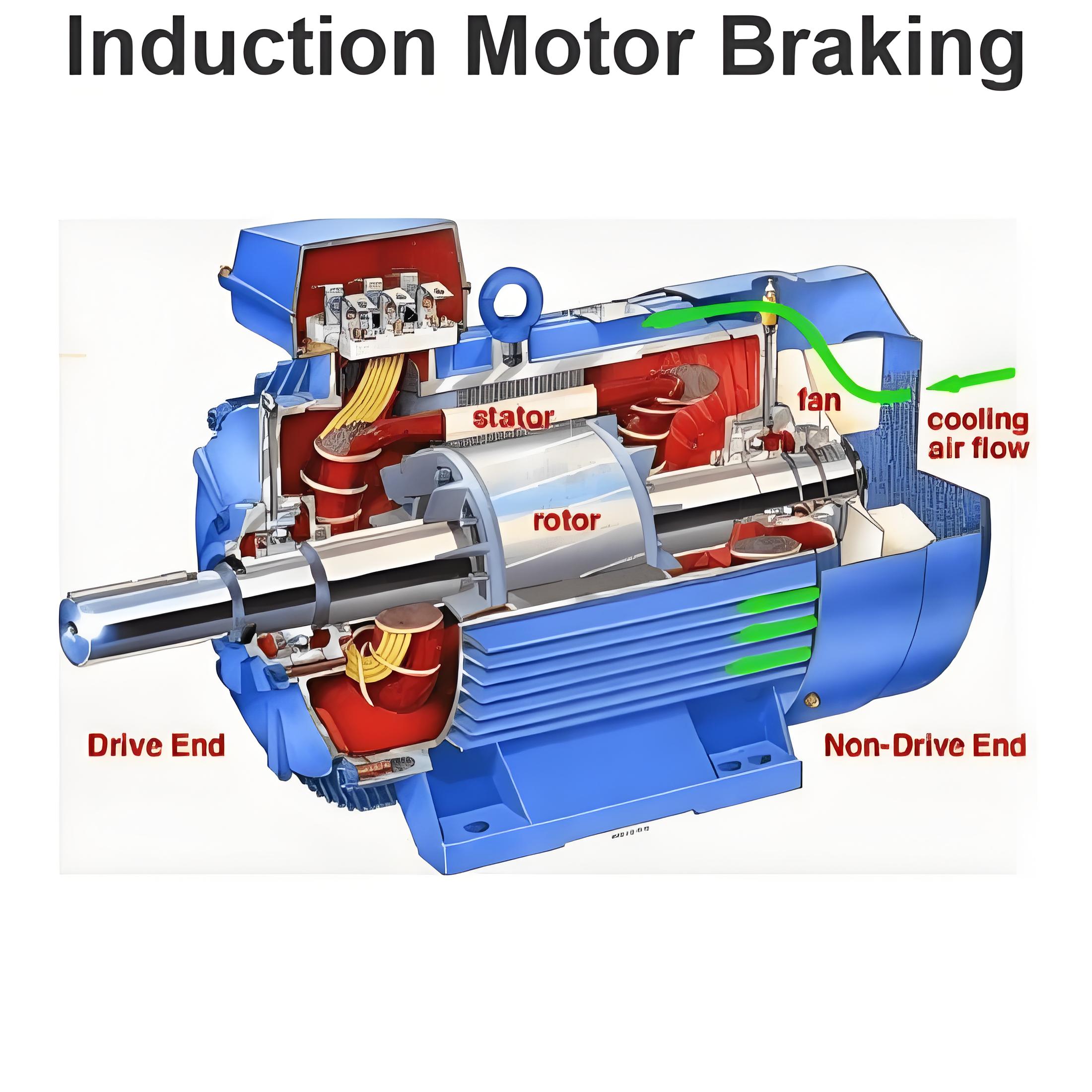

Rotor

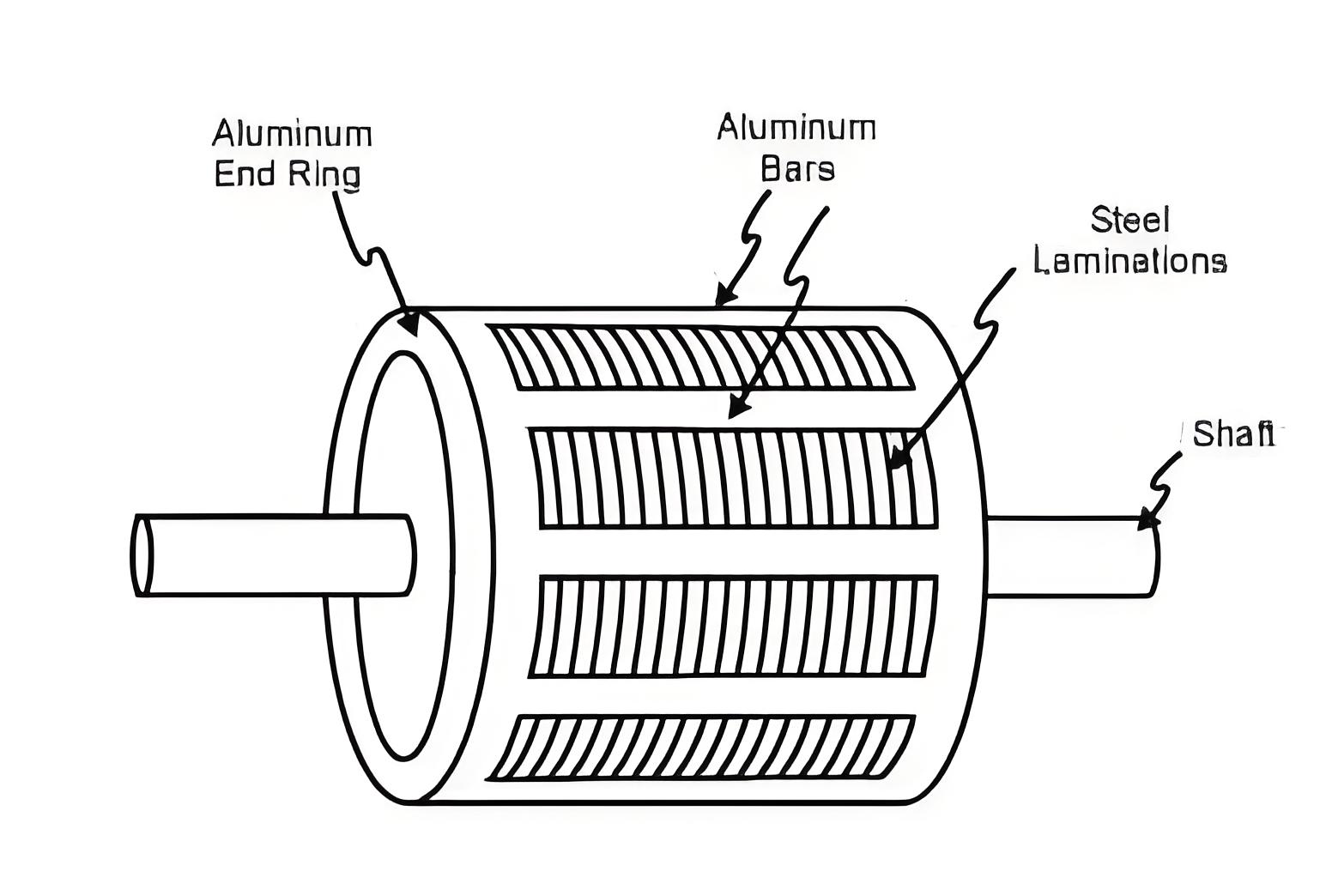

It is the part of the motor that will rotate to provide a mechanical output at a given amount of electrical energy. The rated output of the motor is indicated in horsepower on the nameplate. It consists of a shaft, short-circuited copper/aluminum rods, and an iron core. The rotor core is laminated to avoid power loss due to eddy currents and hysteresis. The conductors are tilted to prevent the cogging effect during start-up operation and to provide a better conversion ratio between the stator and rotor.

Fan

The fan is attached to the back of the rotor to provide heat exchange, so it keeps the temperature of the motor within limits.

Bearing

Bearings are provided as the basis for the movement of the rotor and maintain the smooth rotation of the motor.

Application of squirrel-cage induction motor

Centrifugal pump

Industrial drives (e.g. for running conveyor belts)

Large blower and fan

Machine tool

Lathes and other turning equipment

Advantages of squirrel-cage induction motors

They are low cost

Requires less maintenance (because there are no slip rings or brushes)

Good speed regulation (they maintain a constant speed)

High efficiency in converting electrical energy to mechanical energy (at runtime, not at start-up)

Has better heat regulation (i.e. doesn't get as hot)

Compact and light

Explosion-proof (because there is no brush to eliminate the risk of sparks)

Disadvantages of squirrel-cage induction motors

Speed control is very poor

Although they are very energy efficient when operating at full charge, they consume a lot of energy when starting up

They are more sensitive to fluctuations in the supply voltage. When the supply voltage is reduced, the induction machine consumes more current. During voltage surges, the increase in voltage saturates the magnetic components of the squirrel-cage induction motor

They have the characteristics of high starting current and starting torque difference (starting current can be 5-9 times the full load current; Starting torque can be 1.5-2 times full load torque)

Design change

By changing the shape of the rotor rod, the performance characteristics of the motor, such as speed and torque, can be easily customized to meet specific requirements.

Sum up

When choosing a squirrel cage induction motor, it is necessary to consider factors such as load type, power supply and voltage requirements, environmental and climatic conditions, protection level and explosion-proof requirements, maintenance and maintenance requirements. First of all, according to the actual load type to choose the appropriate motor, such as for high torque, low speed load, you can choose a large power motor; For high speed, low torque load, choose a small power motor. At the same time, it is necessary to consider the requirements of power supply and voltage, so that the power and voltage levels of the motor match the actual application scenarios.

The Electricity Encyclopedia is dedicated to accelerating the dissemination and application of electricity knowledge and adding impetus to the development and innovation of the electricity industry.