System-Level Design for Reliability and Maintenance Scheduling in Modern Power Electronic-Based Power Systems

Power electronic converters will serve as the fundamental components of modern power systems. However, they may suffer from poorer reliability if not properly designed, consequently affecting the overall performance of power systems. Accordingly, the converter reliability should be taken into account in design and planning of Power Electronic-based Power Systems (PEPSs). Optimal decision-making in planning of PEPSs requires precise reliability modeling in converters from component up to system-level. This paper proposes model-based system-level design and maintenance strategies in PEPSs based on the reliability model of converters.

1.Introduction.

Electrifying the world is one of the pragmatic solutions for reducing carbon footprint. Electric transportation, renewable energy generation, electric storage, smart and micro grid technologies, as well as digitalization are essential parts of sustainable electricity systems. These technologies are underpinned by power electronics as the core of their energy conversion process. For instance, the structure of future power electronics-based distribution systems is shown in Fig, which includes AC/DC microgrids. However, power electronics has an Achilles heel: it might be a frequent source of failure and may cause downtime and costs in different applications . For instance, power converters contribution on unplanned downtime in wind turbine systems , and unscheduled downtime costs in Photovoltaic (PV) systems is remarkable. Therefore, power electronics reliability analysis is of paramount importance in the sustainable electric energy development.

2.Reliability of Power Electronics Systems.

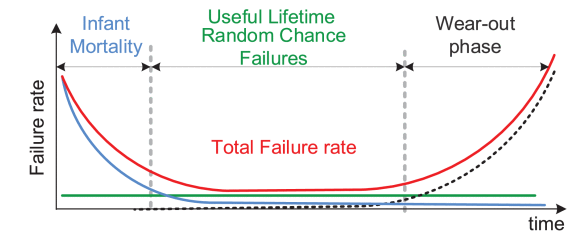

Power electronic converters like other engineering systems follow the bathtub shape failure behavior. It includes the three phases: infant mortality , useful lifetime and wear-out period. In practice, the infant mortality belongs to the debugging process which has been solved before operation. Therefore, the converter will experience random chance and aging-related failures within useful lifetime and wear-out phase respectively as shown in Fig. The random chance failures are associated with overstressing of the components triggered by sudden single event such as overvoltage and overcurrent. Furthermore, the aging failures are associated with the wear-out of power modules, capacitors and Printed Circuit Boards (PCB) solder joints .

3.Proposed System-Level Design for Reliability.

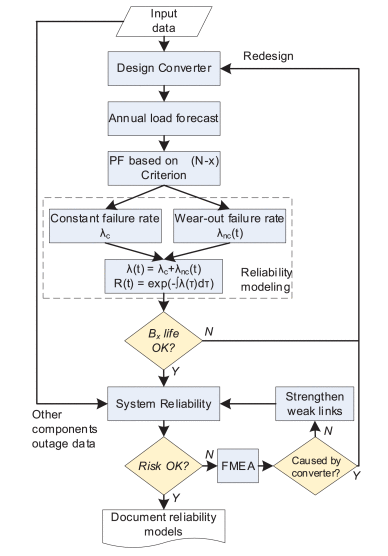

Design for reliability is a process to ensure that a product/system performs its function to meet desired performance under its use environment within a specified time period. The concept of design for reliability has been employed in power electronics engineering in order to design power converters with desired long-term performance . According to this approach, the converter components, especially capacitors and power switches, are selected in such a way that the converter does not enter wear-out phase before its target lifetime . So far, this approach has been applied for single unit converters . The main goal is to design an individual converter to achieve a desired

4.Conclusion.

Power electronic converters are becoming an underpinning technology for modernizing electric power systems while they might be a source of failure and shutdown in such applications. Therefore, reliability enhancement in Power Electronic-based Power Systems (PEPSs) is of paramount importance. This paper has explored system-level reliability improvement in PEPSs by model-based design and maintenance within planning of these systems. Thus, a model-based design approach and model-based maintenance strategies have been proposed.

Source: IEEE Xplore

Statement: Respect the original, good articles worth sharing, if there is infringement please contact delete.

Welcome to our electricity community! Established to facilitate the exchange and cooperation in the electricity industry and bridge professionals, enthusiasts, and related enterprises.