| Brand | Wone |

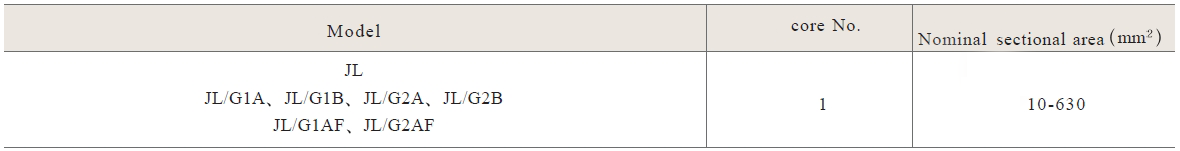

| Series | JL series |

Overhead stranded round wire with concentric lay conductor

1.Application

It’s suitable for overhead transmission line.

2.Standard

GB/T117-2008

3.Model and name

JL aluminum stranded conductors.

JL/G1A common-strength common galvanized aluminum conductor steel reinforced.

JL/G1B common-strength thickened galvanized aluminum conductor steel reinforced.

JL/G2A high-strength common galvanized aluminum conductor steel reinforced.

JL/G2B high-strength thickened galvanized aluminum conductor steel reinforced.

JL/G1AF anticorrosion common-strength common galvanized aluminum conductor steel reinforced.

JL/G2AF anticorrosion high-strength common galvanized aluminum conductor steel reinforced.

JLHA2/G1A common-strength common galvanized steel reinforced type-2 high-strength aluminum-alloy overhead stranded wire.

JLHA2/G1B common-strength thickened galvanized steel reinforced type-2 high-strength aluminum-alloy overhead stranded wire.

JLHA1/G1A common-strength common galvanized steel reinforced type-1 high-strength aluminum-alloy overhead stranded wire.

JLHA1/G1B common-strength thickened galvanized steel reinforced type-1 high-strength aluminum-alloy overhead stranded wire.

Note: The strength model 1, 2 and 3 indicates the common strength, high strength and ultra-high strength respectively, A indicates the common zinc coated thickness, B indicates the thickened zinc-coated thickness.

4.Model

5.Application Condition

a. Applicable for DC and power-frequency AC transmission system;

b.Location of max environment temperature not higher than 50℃;

c.Applicable for overhead laying.

6.Working Condition

The difference of environmental temperature for conductor laying is not higher than 60℃ in laying, the conductor thermal expansion or shrinkage that is caused by the max temperature or min temperature should be taken into consideration , to prevent the conductor being broken under the strain due to the shrinkage stress in the cold season.

The min bending radius of conductor should not be less than 15 times of diameter.